-

Solutions

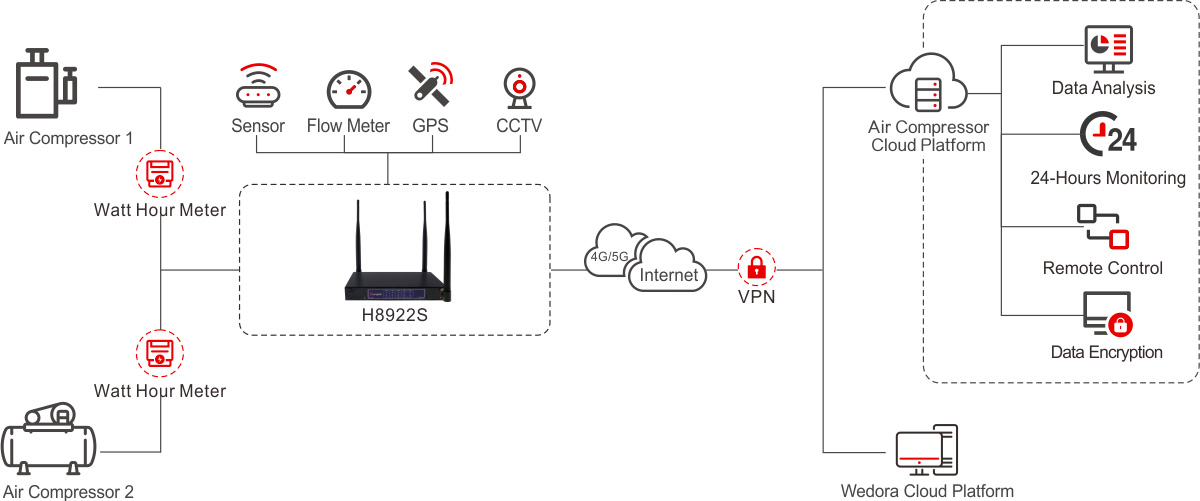

IndustriesEnterprise NetworkLogistics and RetailIndustrial AutomationEnergy ManagementTransportationHealthcareSmart CityFinancial ServiceAgricultureEdge AI Surveillance- Smart Workshop Solution - Intelligent Perimeter Solution - Smart Rescue Vehicle Management Solution - Intelligent Power Distribution Management Solution - Smart Restaurant Management Solution - Smart Oil and Gas Pipeline Management Solution - Smart Store Management Solution - Mining Equipment Condition Monitoring Solution - Gas Station Management SolutionIndustriesIndustrial Robot Injection Molding Machine CNC/PLC Air Compressor Monitoring System Automatic Guided Vehicle VPN Based Remote MonitoringIntelligent Transformer Substation Smart Meter Installation Signal Analyze Power Distribution Solar Energy Remote Monitoring Automatic Meter Reading Intelligent Operation and Maintenance of Power Distribution Room Oil & Gas Pipeline MonitoringTransit Bus Solution Highway Tunnel Surveillance and Controller Video Upload In The Bus Station Railway Networking Solution Public Wi-FiSmart Mobile Nursing Trolley 5G Telemedicine Networking Solution of Ambulance Management Solution of Medical MachinesSelf-service Check Out Machines PoE Wireless Monitoring HVAC Network Solution EV Charging Pile Elevator MonitoringSmart Workshop Solution Intelligent Perimeter Solution Smart Rescue Vehicle Management Solution Intelligent Power Distribution Management Solution Smart Restaurant Management Solution Smart Oil and Gas Pipeline Management Solution Smart Store Management Solution Mining Equipment Condition Monitoring Solution Gas Station Management Solution

- Cellular Products

- Cloud Service

- Support

- Resources

- About Us

- Contact